Training on robust modern mathematical optimization

Mathematical optimization is the preferred tool for identifying the most desirable operating conditions or the most profitable production schedule leading to the best performance, while respecting constraints. Examples of typical problems are: mixing products at minimum cost, making production schedules, maximizing process yield, minimizing losses and increasing throughput in a network. The science of optimization is generally understood and practiced by mathematicians, while optimization problems arise from the activities of engineers. Using the “black box” approach, this training aims to provide simple and robust tools to solve complex problems without having to master programming and mathematics. This training is based on several workshops.

Training objectives

- Learn how to identify an optimization problem

- Understand the problem's features to select the appropriate solver

- Structure the problem in a spreadsheet to solve it

- Use a computer tool to obtain an optimal solution

- Be aware of commercial and open-source platforms

Target audience

- Plant engineers and production supervisors

- Special projects and studies engineers

- Industrial and manufacturing operations directors

- Production systems experts

- Decision makers having to choose the best option while satisfying constraints

Format

- Virtual or in-person

- 50% theory and 50% practical

- Duration: 8 hours

Content

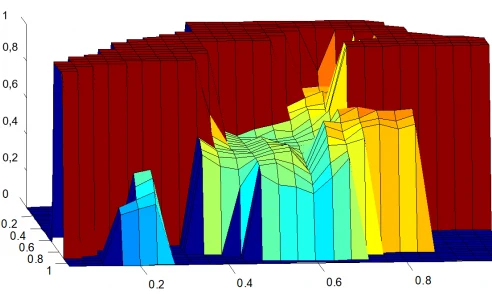

- Introduction: context of use and brief history of optimization, presentation of the main classes of optimization problems

- Description of the elements of an optimization case: formulating the objective, choosing the decision variables and managing constraints

- Difficulties encountered in practice: what are they? How to work around them?

- Solving methodology: black box approach, presentation of some modern and robust algorithms

- Tips for choosing the right algorithm and tools

- Applications in the form of case studies: problems defined in equations, adjustment of non-linear curves, calculations of physical model parameters, minimum travel route (travelling salesperson), optimization of process performance, establishment of tolerances / specifications, production planning

- Overview of commercial and open-source solutions

Requirements

- Install the Différence’s Excel add-in

- Be familiar with computer tools in general

- Be familiar with Microsoft Excel

This training is practical, theoretical elements are very limited. For more information or to book your training, please contact us!