Modelling for Better Operations Scheduling and Throughput Optimization

Simulation modelling solves real-world problems safely and efficiently

Do You Need Simulation?

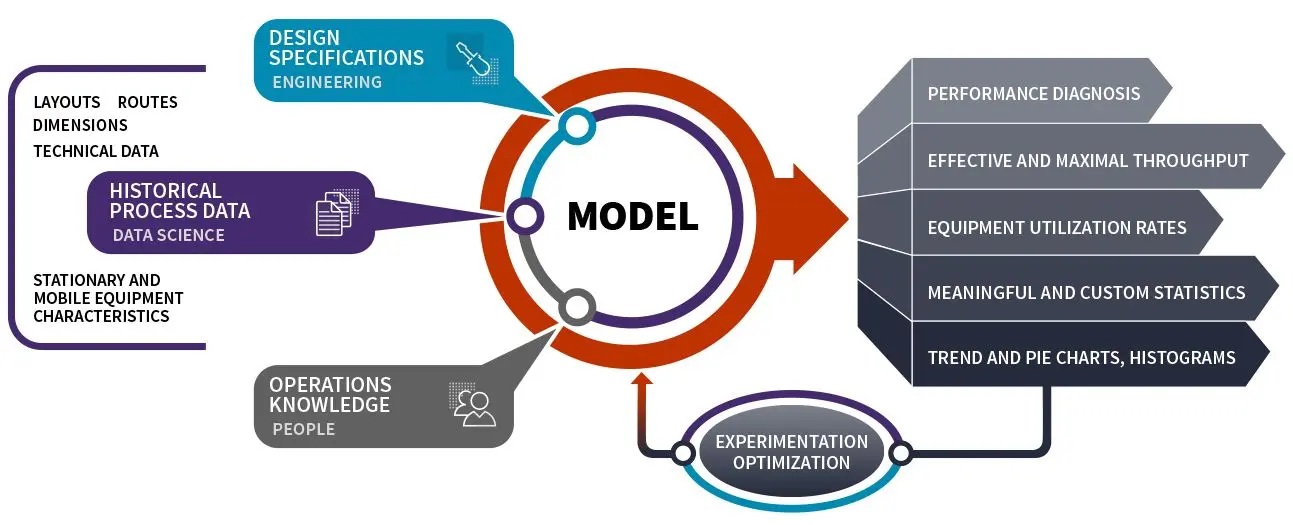

How to determine the effective or maximal throughput, identify the bottlenecks or in which situations the bottleneck moves, establish the best schedule, or evaluate if there are enough resources?

Will it be possible to deliver on time, is it possible to reduce costs or to increase the throughput, what is the most desirable expansion scenario?

These are typical questions expressing an underlying need to model operations using simulation. They may highlight operations scheduling and throughput optimization opportunities.

The Power of Discrete Events Simulation

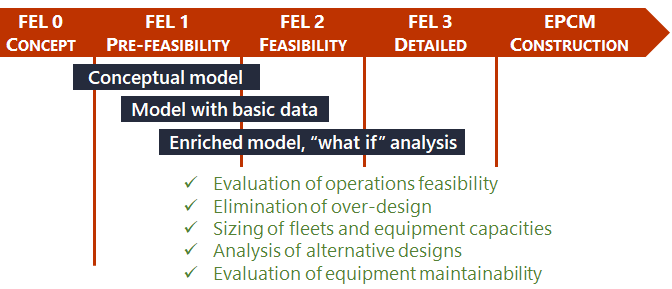

Discrete Event Simulation allows to understand and model operations for which time, variability, movement, and resource availability are critical elements. Combined to complex operations and production schedules, these model elements can characterize process inefficacities or underdelivered throughput. Learn more by reading our white paper on what is a model.

Discovering underlying interactions and key drivers provides intelligence on the whole process. A better production planning or operations scheduling enhances the productivity, augments the throughput, and can help justifying investments. A global view for fact-based decision-making!

Our Globally Recognized Expertise

Our consultants have extensive experience in developing complex models for many applications. In addition to having developed unique specialized libraries for bulk materials simulation, traffic and maintainability, they have published scientific peer-reviewed articles and participated in several international conferences. Our consultants are also operational excellence and mathematical optimization experts. Imagine the potential to uplift your throughput!

Our modeling approach is practical. We make decision-making tools accessible and democratic, easing the configuration of scenarios and the interpretation of results. We deliver highly performant and flexible simulation models!

Sharing our knowledge with our clients is part of our culture. We offer training sessions on the practical topics, for instance: Monte-Carlo simulation, robust optimization, and discrete event simulation.

Examples of Simulation Projects

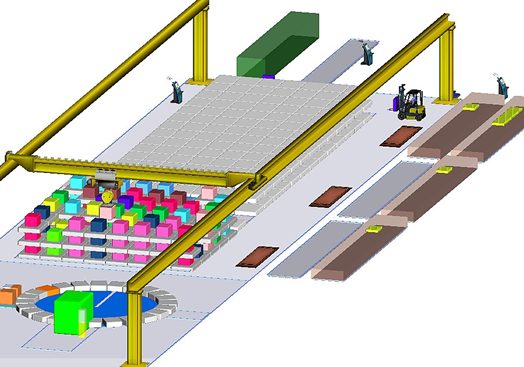

Mining operations, ore haulage

- Detailed Life-Of-Mine development and production

- Surface and underground mining operations

- Materials handling logistic and haulage

- Ore conveyors network

Bulk material handling

- Ore concentrators and processing plants

- Smelting complex and casthouse operations

- Containers and bulk material port terminals

Supply chains, distribution networks

- Rail and road transportation

- Mine-to-ocean supply chains and logistics

- Warehouses, distribution centers and logistical networks

- Strategic planning of asset expansion to improve supply chains

Light industrials, airports and others

- Tissue paper converting and packaging lines

- Mechanical and mobile equipment maintenance shops

- Airport baggage handling and passengers flow

- Industrial agriculture and greenhouses

- Food, beverage and packaging facilities

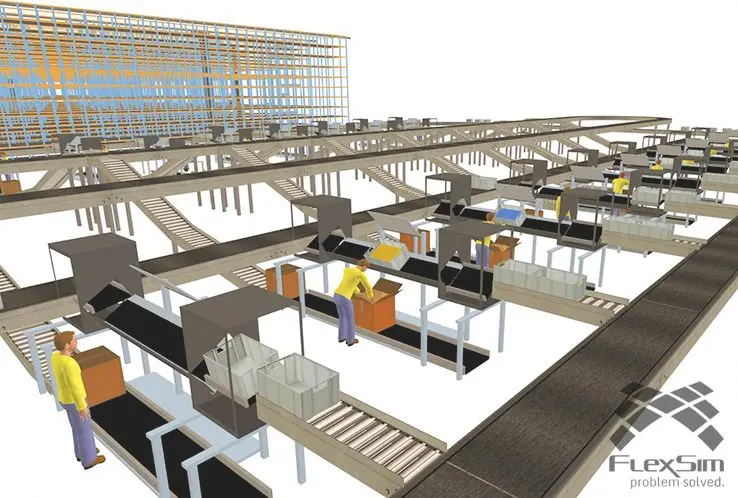

FlexSim Partners and Software Support

Flexsim is a powerful, capable, and easy-to-use 3D simulation software. It lets you model and improve existing and proposed systems:

- Model a real system in a native 3D virtual environment

- Account for real-world variability with FlexSim’s vast array of statistical distributions and random numbers

- Run simulation using the model to test “what if” scenarios—without needing to change things in the real world

Learn more: www.simulking.com/flexsim

Différence offers support to users of the following simulation software: Flexsim, Anylogic, and Simio.

Selected Readings on Simulation

Here are some of our featured articles and past conference slides on operations simulation and optimization. These are documents you can print and share. More material, including peer-reviewed scientific papers, can be found on our Documents webpage.